Understanding Thermoformed vs. Non-Thermoformed Paddles

Pickleball paddles come in various construction processes, but two primary methods stand out: thermoformed and non-thermoformed. It's important to know what you are buying.

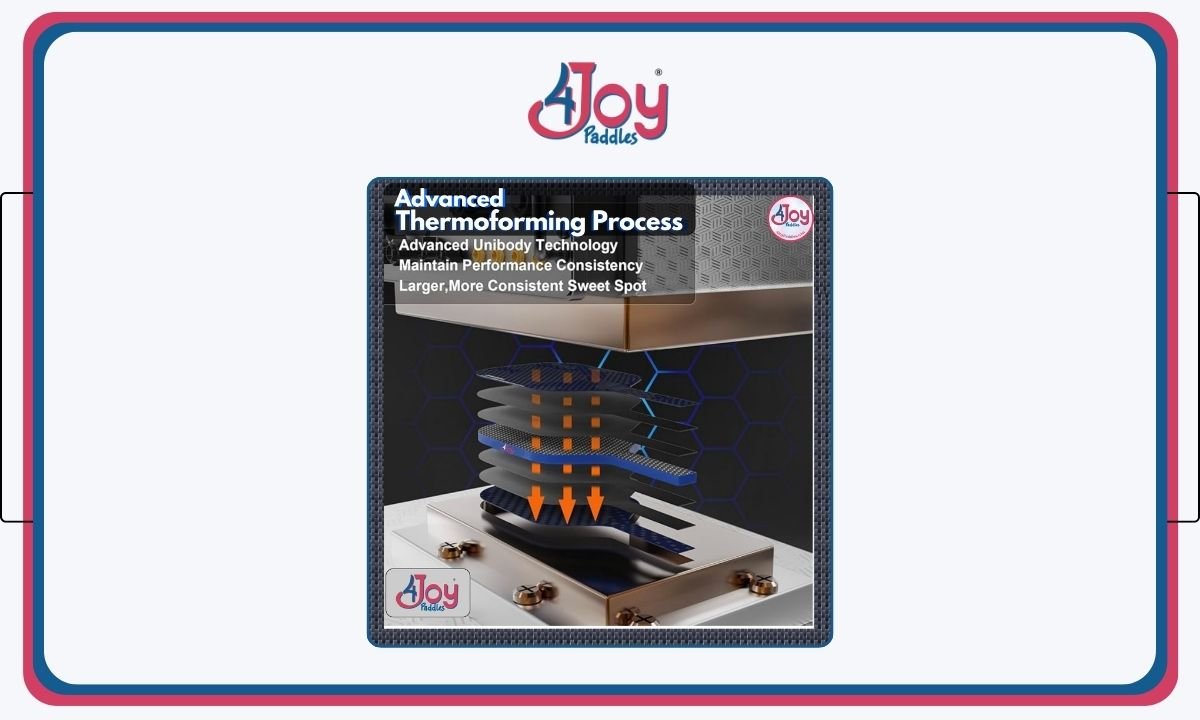

Thermoformed Paddles are crafted using a process called thermoforming, where materials, typically composite or polymer and carbon fiber, are heated into a molded shape. The application of both heat and pressure, combined with the use of epoxy resin, and a foam injected edge, ensures that these individual pieces are effectively fused together. The result of this meticulous process is a seamlessly integrated, or "thermoformed", pickleball paddle with consistent thickness and weight distribution, offering enhanced durability and performance.

Non-Thermoformed Paddles are often constructed using layers of cheaper materials such as wood, fiberglass, or carbon fiber, which are laminated together. While they may be a cheaper cost option, they have a different feel and play style compared to thermoformed paddles and can vary more in terms of weight distribution and consistency.

Thermoformed Pickleball Paddle Advantages:

Consistency in Performance

These paddles offer consistent power and feel, which is crucial for a player who values precision and predictability in their paddle.

Durability

Compared to less expensive cold pressed “sandwich paddles,” thermoformed paddles are more durable. The unibody design, resulting from the thermoforming heat pressed process, reinforces the paddle's structure, making it almost impossible to break. This durability ensures that players can rely on their paddles over extended periods, even under rigorous playing conditions and not have to replace their worn out paddles as often.

Larger sweet spot

Thermoforming, creates a unibody structure with seamless integration of the paddle components. This integrated structure leads to enhanced rigidity and stability across the entire paddle face. A more stable paddle face can absorb and redistribute the impact of the ball more efficiently, which expands the sweet spot compared to sandwich style paddles. This leads to more stability on off center hits.

More power

Due to the unibody construction, thermoformed paddles typically produce more power than other paddles. With the 16mm thick responsive core of 4Joy paddles, players can still maintain control and ‘touch’ at the net without sacrificing power.

Manufacturing Process

The manufacturing processes for thermoformed and non-thermoformed paddles differ significantly. Thermoformed paddles involve heating and molding layers of material, followed by finishing touches such as adding grips and edge guards. The application of both heat and pressure, combined with the use of epoxy resin, ensures that these individual pieces are effectively fused together. The result of this meticulous process is a seamlessly integrated, or "thermoformed", pickleball paddle.

Non-thermoformed paddles, however, require simple lamination of multiple layers of materials, followed by shaping and finishing.

Cost Considerations

Thermoformed paddles often come with a higher price tag due to the labor intensive and technical production process resulting in precision and consistency compared to the less expensive non-thermoformed laminated paddles. But as the saying goes “you get what you pay for”

Thermoformed pickleball paddles represent a blend of modern technology and innovation. Their durability, consistency, and balance of power/control make them a better choice for players looking to enhance their game.